In this how to cut silicone guide we will walk you through all the info needed to safely and easily cut silicone. We will also provide much needed info on what is silicone and why do we need it in our lives

Whether you are a frequent baker or an artist who likes to make resin jewelry, you must have heard about silicone.

It is a revolutionary gift of science that is non-reactive in the face of extreme temperatures and environmental conditions.

Thus, this stable polymer has become a popular material used in electronics, automobiles, aircraft, and more.

It is also commonly used for making sealants and in HVAC systems. But that’s not all! Silicone cookware and bakeware have become hugely common.

They are also used in resin art and sculpture-making. It’s a tough material that doesn’t get destroyed easily.

So, the question is, how do you cut silicone? The material is not difficult to cut, with the right tool and method. Let’s take a look!

So the question remains – How to Cut Silicone

It takes a complicated process to make silicone, a material that has become an essential part of every industry.

It is a highly durable material, but it sometimes needs to be cut for various uses. Using the right methods and devices, cutting silicone can be as smooth as cutting butter.

Let’s start by discussing the four ways used for cutting silicone as used by industries.

a) Manual Cutting

The most convenient way of cutting industrial silicone is by using the manual technique using a knife, box cutter, wire saw, etc. A template or stencil is used in the process.

Manual cutting is cost-effective because it does not involve expensive tools or machinery.

But don’t forget to consider the cost of materials wasted and of rework. Also, consider the fact that the method might cause injuries.

Besides, manual cutting can lead to low quality of finishing, which can look unappealing to potential customers.

b) Die Cutting

For die-cutting silicone, dies or metal tools with sharp edges are used. The equipment may be of two types – rotary or flatbed. Rotary die-cutting is much faster than flatbed die-cutting.

It is also more accurate. However, this means that they are costlier.

Dies cut the silicone with the help of the exertion of pressure. If the finish is unsatisfactory, it is the result of a scrapped tool. This can add to the cost and time of the project.

But in large-scale production, the production of silicone parts of the same shape brings down the per-unit price.

c) Water Jet Cutting

Water jet cutting is a unique method of cutting silicone at industrial levels without the use of tooling.

This means that it is a cost-effective method. Besides, with this method, it is possible to make revisions and complete the project in less time.

It is used in prototyping and can handle up to a medium level of production. Another advantage of this method is that it can give smooth edges that bond easily.

It is also good at creating angles, holes, and other cuts. High-end factories use CAD for better accuracy.

d) Abrasive Water Jet Cutting

Abrasive water jet cutting is an advanced form of pure water jet cutting. It is such a powerful method that it can be used to cut metals.

As for silicone, abrasive water jet cutting may be useful in cutting metal that’s coated with silicone rubber.

In this method, the water streaming out at high speed from the nozzle contains abrasive sand.

The water accelerates the sand to cut the material at hand with higher accuracy by applying high pressure on it. Thus, the features of pure water jet cutting reach a new level.

e) Laser Cutting

Laser cutting is a high-speed method of shaping and cutting materials at industrial standards. The edges are smoothly cut, without any sign of chipping.

It can be used to cut even the thickest pieces of silicone at high speed, making it one of the best cutting technologies.

It helps to achieve high levels of accuracy, and laser beams are also great at engraving silicone.

That is why laser cutting is often used in making jewelry, toys, and more. That’s because this method allows a high level of detail and precision.

These methods are used at industrial levels, and each has its own advantages. They cater to different types of technical requirements of a business or industry.

Cutting Silicone Manually for Individual Use

While the above techniques are highly useful in cutting silicone or silicone-layered metals, they are not for personal use.

You may need to cut silicone molds, sheets, or hoses if you like to handle small tasks of hardware or enjoy art. How do you cut silicone in that case?

a) Cutting Tool

Cutting silicone manually demands sharp tools. The primary tool here is a sharp cutter, which may be a utility knife, scalpel, a curved cutting blade, or a mold cutter.

Your cutter needs to be extremely sharp, and preferably new so that you can get smooth results.

b) Lubricant

Believe it or not, soap and water can come in really handy while cutting silicone.

You’ve guessed it right – it works as a fabulous lubricant! Soapy water can make the blade just glide across the silicone and maintain its sharpness.

But you’ll only need a small amount as silicone oil acts as a lubricant. Besides, the slippery water won’t take long to turn into a hazard and cause you to bleed. So be careful.

c) Clamp

Clamps may also be used as a cutting guide to cut silicone hose or molds. There are different types of clamps available for this purpose.

T-Bolt clamps and liner clamps, made of stainless steel, are used to cut hose, while vise-style clamps can help to cut molds of large volumes without tiring you out.

Other tools and accessories that will also be helpful to cut silicone include the following:

- Gloves: Wear gloves while cutting silicone, as that will protect your hands from a possible injury.

- Marker: Chalk is a delible marker to draw lines for measurements. You can also go for sharpies or pens for more permanent marks.

- Straight Edge/Stencil: The shape in which you want to cut the silicone can be perfected with a stencil or straight edge scale.

- Magnification: If you want accurate cutting, a magnification tool may be able to help you.

Not all tools will be required for all types of silicone cutting. In general, if you’re not working in a factory, you may need to cut silicone hose, sheets, or molds.

Cutting Silicone at Home

In general, you can cut silicone by following the steps below:

- Start by taking a clamp, scalpel, blade, or any other cutter. Make sure that it has a new and sharp blade.

- Take the silicone mold, hose, or sheet, and mark with chalk or sharpie.

- If it is a sheet, lay it flat on the workstation and using a straight edge or stencil, mark the shapes or lines.

- If you’re using a clamp, tighten it securely to get a line to use as a cutting guide.

- Using your cutter, start cutting the silicone.

- If you want to use soapy water, apply a small amount of it.

- Remember to run the knife away from yourself and never in your own direction.

There you go! You now know the easy way to cut silicone at home. These methods can come in handy while cutting different types of silicone.

Related: How to cut wood without a saw

Whether you’re roughly cutting molds or want to make precise cuts on sheets or hose, the key is to find the right cutting knife with a sharp blade.

Uses of Silicone:

Silicones are now instrumental in a large number of industries. That’s because of the properties of silicone that enhance the products that are made out of them, like flexibility and resistance against heat.

The best thing is that silicone can be made into different forms, including solid, semi-solid, oil, and other consistencies.

Silicone is used in making the following:

a) Energy

Silicone is popularly used in solar panels or other photovoltaic equipment. The material can make these devices more efficient and durable. As a result, they become more cost-effective.

Silicone can withstand the heat and the rays of the sun for a long time. Naturally, it’s one of the primary choices for the devices.

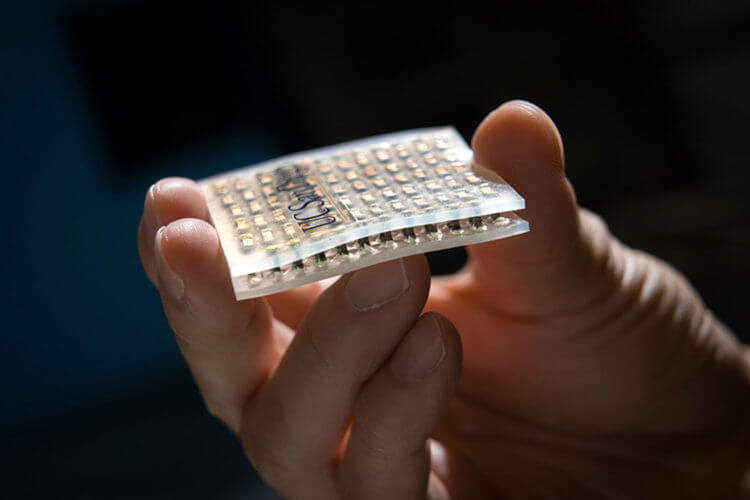

b) Electronics

Electronic devices and their components are frequently made of silicone. If you’ve noticed, keypads and keyboards are often made using silicone. From mobile phones to home entertainment appliances, silicone rules.

Interestingly, it is also used in LED lighting and electronic transmission. The material’s dielectric properties are one of the reasons behind this. Another reason is its thermal stability.

c) Personal Care

Silicone is often used in grooming products like deodorants, hair products, sunblocks, cosmetics, and more. They do not leave the whitish residue that deodorants leave.

Hair products with silicone make your tresses shiny and smooth. Silicone content in cosmetics helps create better color payoffs and raises the SPF in sunblocks. They also make lotions and cleansers smoother.

d) Aviation and Automobile

Silicone is a material that can handle high levels of stress and extreme temperatures. It’s durable and strong, too.

So, sealants and adhesives made of this material are frequently used in the aviation or automobile industries for doors and windows, wings and edges, engine gaskets, and more.

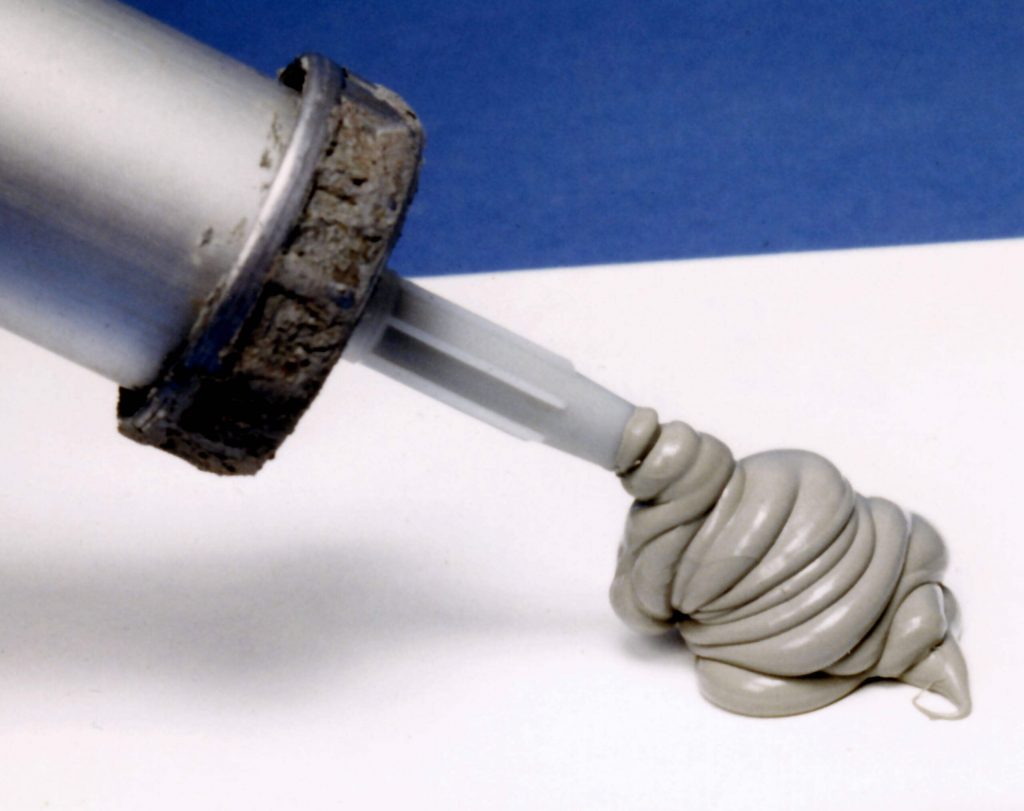

e) Construction

In the construction and renovation industry, silicone has become a key material. It is used in making sealants and caulks.

It is also helpful in enabling architecture that’s energy-efficient and sturdy. Silicone can also come in handy in the prevention of damage as a result of moisture-induced bacteria.

f) Molds

Silicone is popularly used in making both temporary and permanent molds. From resin to wax, from soap to clay, silicone molds work for everything since the finished products are easy to remove since silicone is flexible. Plus, silicone molds can give amazing details to your artwork.

g) Kitchenware

Silicone cooking and baking utensils have become vastly popular in the past few years, for multiple reasons. Silicone stays strong against heat. It is flexible and easy to use.

Silicone utensils are also super-easy to clean. Another great advantage is that it is free from odor and color. Plus, all kinds of food are easy to remove from silicone utensils.

h) Paints

These days, paints with silicone in them are often used for coating the walls of houses and even public properties. That’s because silicone is not affected by cold or heat, and it neither melts nor freezes.

It also doesn’t dry out or crack. It also doesn’t let roads or oil rigs corrode easily.

i) Swimming Accessories

Silicone is often used in making swimming goggles, masks, or caps. That’s because it is capable of keeping water out. Besides, silicone is light and breathable, which makes it an ideal material for making swimsuits.

Yes, silicone can also be used as a fabric for making flexible sportswear. Amazing, isn’t it?

Thus, silicone has taken over a large number of industries. From engineering accessories to electrical insulation, silicone is everywhere and in different forms, from grease to resin.

Why Silicone is Popular

Silicone is popularly used in different industries because of its various properties. It is a poor conductor of heat and electricity and remains stable in a wide range of temperatures, from -100 C to 250 C.

It also does not react to chemicals and is non-toxic. Besides, it does not allow the growth of microorganisms.

It repels water, but it’s highly permeable by gas at different temperatures. At the same time, it is resistant to oxygen and ozone.

As an FDA-compliant material, there is no need to worry about any health hazards caused by silicone. As a result, it is suitable for medical equipment and cooking utensils.

Conclusion:

You have to remember that the results achieved by industrial methods of cutting silicone can always be highly accurate and quick. It will be challenging to get the same results when you cut silicone at home.

However, if you follow the steps we have mentioned and the right tools, it will not be hard at all.

With tools that are sharp enough, you will be able to cut through silicone like butter. A magnifying tool will be helpful in making intricate cuts. Don’t forget to be careful and slow while cutting silicone manually.

Otherwise, you may end up hurting yourself. But if you are cautious and regular, you will be able to master the art of cutting silicone at home soon.